Ultrafiltration with ceramic membrane for flexographic solvents recovery

Ultrafiltration with ceramic membrane for flexographic solvents recovery

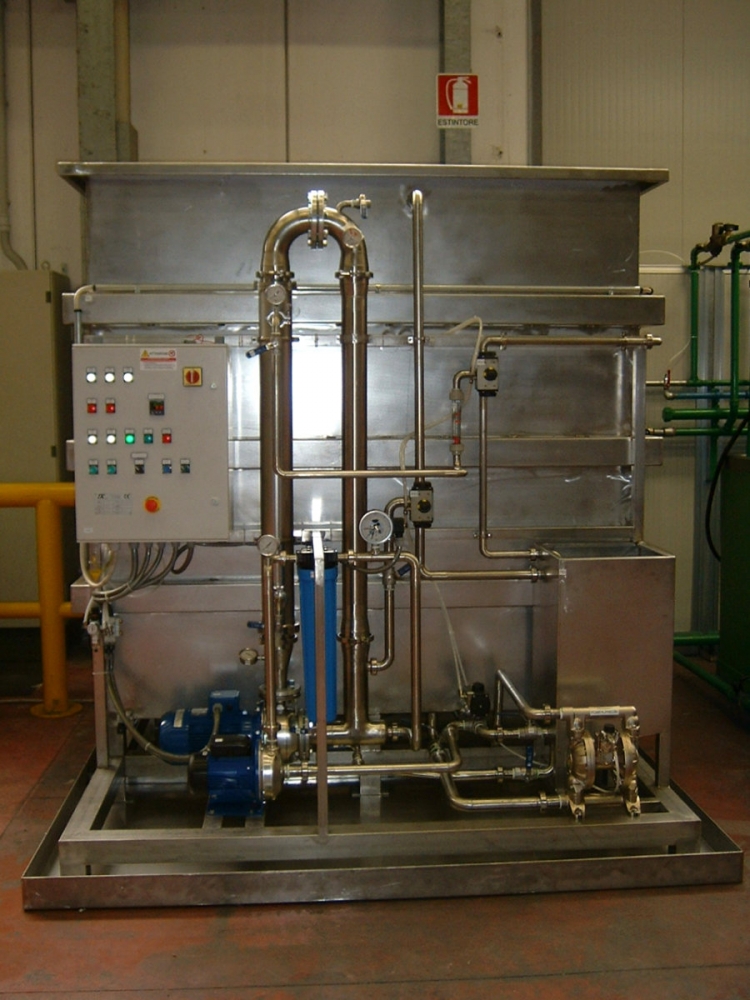

Ceramic membrane ultrafiltration machines for flexographic solvents recovery

Flexographic printing, known as flexo, or rotogravure printing (roto), are nowadays employed in the relization of prints on numerous types of absorbent and non-absorbent materials, such as glass, plastic, metal, paper and wood. Printing is direct, in that the ink is transferred directly to the support to be printed by applying a light pressure on a cylinder.

Solvents can be regenerated with our machines, conceived as automatic washing machines for components of the flexo and roto type. They are in fact extremely versatile for washing elements such as inking or impregnation trays and rollers used in printing lines.

The main feature of the washing system is that of being fully pneumatic. This means that it does not require any electric current, making it the ideal solution for all kinds of washing with solvent or water and detergent, since the risk of fire caused by products used in washing operations is eliminated.

Moreover, ceramic filter membranes are used, which chemically resist all types of solvent.

TA is prepared to manufacture this type of machinery customizing the useful washing dimensions according to specific customer requirements during the design and construction phase. Furthermore, we provide pilot plants for field testing.

Discover all other products:

We study the most suitable solution for your company.