Ultrafiltration for oil emulsion and degreasing bath treatment

Ultrafiltration for oil emulsion and degreasing bath treatment

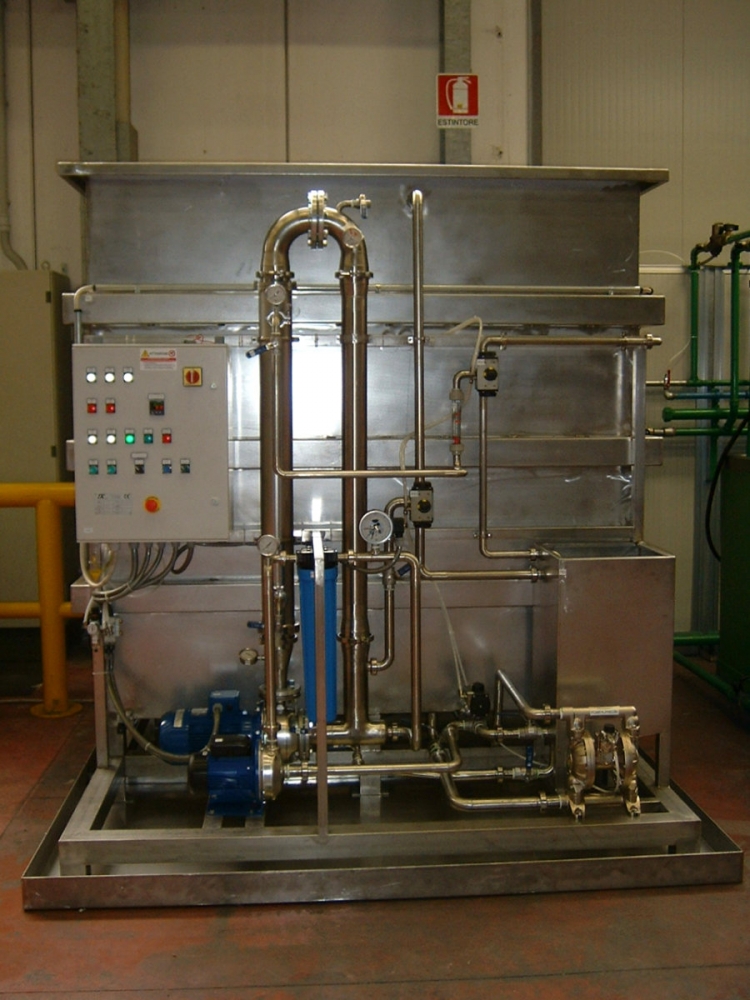

Ultrafiltration equipment for oil separation

Water / oil emulsions are present in many industries.

Oil emulsions are typically used in metal cutting and metalworking processes as coolants. These emulsions tend to become polluted over time with the risk of being disposed of as hazardous waste and replaced.

Furthermore, in the mechanical, steel and in general processing of raw materials, degreasing is a necessary step before any other process and is carried out with the aid of an aqueous solution containing detergents. The detergents emulsify the oil present on the materials to be treated; for this reason in the degreasing baths the concentration of oil tends to increase up to the obligation of replacement and renewal, under penalty of loss of effectiveness.

Another case is constituted by the detaching solutions, used for example in aluminum die casting.

TA systems, based on an optimized combination of high efficiency oil separators and ultrafiltration machines, allow the emulsion to be physically broken, separating the oil that can be delivered to the Oil Recovery Consortium and obtaining water reusable in the production cycle. In this way, disposal costs can be reduced and the environmental impact of processing considerably lowered.

TA is able to customize the equipment for each customer, also by means of tests with pilot plants. We therefore remain at your disposal for the discussion of each specific case.

Discover all other products:

We study the most suitable solution for your company.