Ultrafiltration and reverse osmosis for paints, pigments and electrodeposition paints

Ultrafiltration and reverse osmosis for paints, pigments and electrodeposition paints

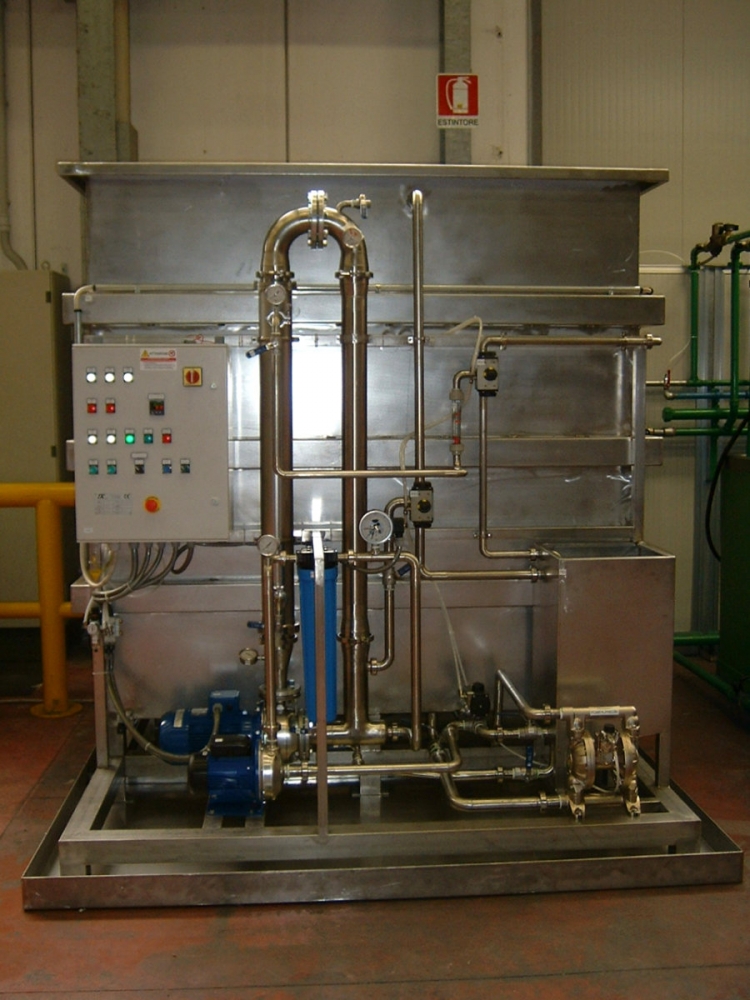

Ulltrafiltration machines and reverse osmosis for graphics, inks, water-based paints and cataphoresis lines

This type of machinery is used in the printing and graphics industry, in the paint manufacturing sector and in most painting processes.

The types of effluent generally treated are cleaning waters from printing and screen printing frames, water containing pigments and printing pastes, paint factory or paint shop spray booth wastewater, water containing vinyl based adhesives and photographic bleaching and fixing liquids.

These waters are composed of water based paints (3-10%), colorant pigments, impregnating liquids and wood primers, various additives, dirt, surfactants, traces of hydrocarbons (solvents), vinyl adhesives or various oils.

The aim of the treatment is to concentrate the effluent for volume reduction prior to disposal or water reuse.

At the end of the process it is possible to recover high quality water (eventually demineralized and therefore free of salts), which is reused in the production cycle as cleaning water.

Treatment of cataphoretic and anaphoretic paints is a particular, still very important application. In cataphoresis plants the UF system is used for the recycling of paint in the surface treatment tank. At the same time, water containing solvent and an excess quantity of mineral salts is extracted in order to maintain the balance of the cataphoresis bath.

Discover all other products:

We study the most suitable solution for your company.